Baking and the Chorleywood Connection

The British Baking Industries Research Association (BBIRA) at Chorleywood, 1949 to 1996

The British Baking Industries Research Association (BBIRA) was one of a number of Research Associations set up by the Government before and after World War 2 to serve industry. It acquired Chorleywood Lodge, situated on the opposite side of the A404 to Chorleywood Common, a gracious, double-fronted building well shielded from the road by a row of tall trees. It had curved bay windows either side of the front door and moulded plaster ceilings.The grounds were extensive and included an orchard, a sweeping curve of beech hedge and some beautiful trees from the original garden including a giant redwood visible from several miles.

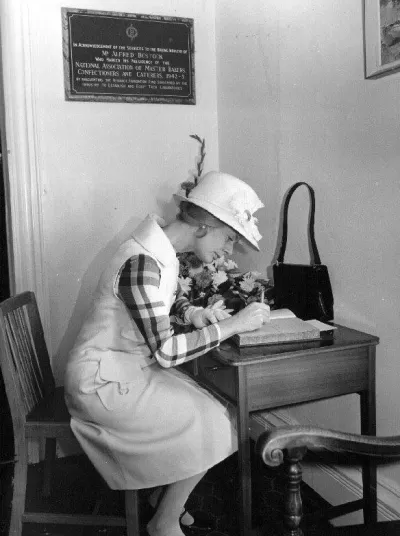

The BBIRA premises were formally opened by the late Princess Marina, Duchess of Kent in 1949. The west and north wings of laboratories were added in 1961. BBIRA was concerned with baked goods, their ingredients, and bakery technology and equipment, and in 1966 it merged with the Research Association of British Flour Millers (RABFM) at St Albans to become the Flour Milling and Baking Research Association (FMBRA). RABFM had been founded in 1923 and brought expertise in milling, starch, sugars and nutrition; it was responsible, amongst other things for the ‘National loaf’ in the Second World War and for working out how Vitamin B was distributed within different parts of the wheat grain. A new East Wing was built at Chorleywood to accommodate the larger combined establishment and its 100-140 staff during 1970, and it was declared open by the present Duchess of Kent in March 1972.

Among many other achievements, the Chorleywood Research Association will always be remembered for the Chorleywood Bread Process (CBP), a novel process developed in the early 1960s using a commercial mixer designed at Chorleywood. The CBP transformed the bread baking industry in this country and a number of others including Australia, New Zealand and South Africa. Later its use was extended to other yeasted products, and soon most cream crackers were also made using the Process.

Before the CBP, a typical UK long fermentation breadmaking process included an intermediate proof during which the dough stood in huge wheeled pans for three hours: production was thus limited by the space they occupied and the batch process was labour-intensive as the pans had to be moved and the dough tipped out manually. CBP doughs were mixed faster and harder and needed to be proved for a much shorter time, making continuous production feasible. Improved performance of English wheats was an important extra benefit at a time when the stronger North American wheats traditionally used had become prohibitively expensive. The CBP could be used for most bread including crusty French sticks, and the Process won BBIRA a Queen’s Award for Industry in 1966.

The CBP has attracted much unjust criticism in the media. It is true that the longer fermentation period of traditional methods can allow more flavour components to be formed, but it is inefficient and expensive to produce bread in that way. Lord Rank, on one of his visits to the Research Association, famously said that when he was in the Savoy eating half-a-dozen oysters it was not the bread that he wanted to taste! While most people don't eat oysters very often, they do often eat bread with stronger-tasting foods when the taste of the bread becomes less important - an example for many might be a cheese sandwich.

English wheats are generally lower in protein than North American varieties due to a combination of factors such as growing conditions, day length and differences in weather. Carbon dioxide and other fermentation gases begin to be released during mixing and initial moulding of dough, and gluten protein surrounds the tiny bubbles which expand to make the dough rise as more gas is released during proof and the early stages of baking. The strength of the gluten bubble walls determines the nature of the bread crumb - less gluten leads to a weaker, more open structure.

Moreover, wheat quality in England is subject to wet weather at harvest time. In some years damp wheat begins to sprout and its starch to break down. This results in stickiness of the bread crumb, but that is obviously not the fault of the CBP.

Loaves made with English bread wheats rarely rise quite as much as those made with North American ones, but the CBP has enabled reasonably good quality bread to be made with them against the odds. Differences in the quality of loaves made with flour from US and British wheats were not considered sufficiently important to justify the rising cost of importing wheat from the USA or Canada.

The popularity of sliced bread also increased in about the same time. It is very convenient for sandwiches, but the loaves have to be more lightly baked and hence with a softer crumb because crusty bread cannot be sliced in a continuous production process as it jams the blades of the slicing machine. The need for less power is a cost-saving for the baker while the bread still meets the needs of many consumers, although it may be somewhat less 'tasty'.

The CBP alone is often blamed if the bread is perceived not to be ‘as it used to be’, but a well-baked loaf made by the CBP from the flour of unsprouted English wheat of reasonable protein content is very acceptable and good value for money. Today there is a very wide choice of bread available, including crusty bread made using the CBP or traditional methods, and people can buy according to their preference, how they plan to use the bread, and how much they want to spend.

An Intervention laboratory and conference suite were added in 1988 after FMBRA became the national Intervention testing centre. (Intervention was a temporary government scheme for retaining excess breadmaking wheat in store rather than letting it be sold for animal feed.)

Pivotal to the work at Chorleywood were pilot-scale flour mills and bakeries for making bread, cakes and biscuits. A small-scale extruder was later added for work on products such as breakfast cereals and snacks. The Research Association thus had equipment for studying differences between wheats, plant settings, and additives and ingredients; in flours and baked products. Several widely-used methods of evaluating uncooked mixes and products were developed at Chorleywood. For example, the Cone Indenter was used to assess the texture of crumb by applying weights to the cone set with its tip just resting on a sample of bread or cake at timed intervals until the structure collapsed. Flavour was assessed by taste-panels drawn from the staff.

The wheat and flour testing and analytical laboratories provided essential back-up for the milling and baking industry. The optimum amount of water for each flour, the physical properties of its doughs, and how well they fermented were measured. Flours only available in small quantities, perhaps from wheat breeding programmes or harvest surveys, would also be baked, and because loaves could be prepared from as little as an ounce of flour, ingredient components isolated in research laboratories might be tested there. Many routine analyses, like protein and moisture content, were performed by the analytical laboratories. Non-routine assays were set up or developed as required.

Engineers and mathematicians worked with pilot-scale mill and bakery staff to develop better equipment for production and monitoring. Promising prototypes were tested in commercial plants and some were manufactured. Of two novel patented mixers, one designed in 1990 is still used in UK, France, Spain, Germany, Greece, USA, South Africa, Australia and New Zealand. This department also advised on experimental design, computing and the statistical analysis of results. In the early years, liaison officers visited bakeries regularly or by request to advise owners, and they could produce plans for new bakery buildings and layouts.

A microbiology laboratory was concerned with safe manufacturing practice, distribution, retail and storage conditions for baked goods and their fillings. Ways of extending safe shelf-life by better packaging were sought. Checks were made for growth of yeasts, moulds and bacteria, and strains were identified. Laboratories specialising in starch, protein and fat studied more fundamental flour components and dough ingredients and their effects in baking.

Comprehensive library and information departments were available to members as well as staff. Digital baking information systems compiled at Chorleywood were made available on-line and thus accessible to members throughout the world. Research Association staff were also responsible for distributing the results of their research in regular publications, answers to specific enquiries, translations, legal advice and occasionally appearing in court as expert witnesses.

Staff travelled widely to speak at meetings and conferences, publishing work in open scientific journals, Research Association reports and newsletters, or to advise bakeries worldwide. Scientists and FMBRA members had always visited Chorleywood from all over the United Kingdom and from many countries of the world, and continued to do so.

What happened to FMBRA?

When Research Associations were first established they were funded approximately half by Government and half by their industry, mainly through member subscriptions. The Government planned to gradually withdraw funding until they were entirely industry-supported, but in practice this never happened. Much of the shorter-term research, technology and service work continued to be paid for through member subscriptions, flour levies or charges for particular services. As time went on, mergers between member firms meant that subscription income came mostly from fewer, larger organisations, who naturally had most say in the work of the Research Association. The more long-term and basic research, then regarded as an important resource for industry, was funded by Government grants that became increasingly focused and more rigorously overseen and outside competition for them grew. After Britain joined the Common Market European Community grants were awarded to groups of scientists often from several countries, who were able to study different aspects of the same problem according to their expertise and equipment and visit one another regularly for meetings and discussions.

On 1 January 1995, FMBRA merged with the larger Campden Food and Drink Research Association, also founded in 1923 to cover fruit and vegetables, and became Campden and Chorleywood Food Research Association (CCFRA). The Chorleywood laboratories moved to the Cotswolds in 1996 where the Chorleywood Building at Chipping Campden was opened shortly afterwards by Princess Anne. Chorleywood staff brought cereals expertise, and the Research Association’s horizons were broadened to encompass most of the food and drinks industry. After a further merger with the brewing industry’s research association, it is now known as Campden BRI, and is still at Chipping Campden serving a much wider group of industries; the basic research element has been largely lost.. The buildings at Chorleywood were sold and converted to apartments and to the Chorleywood Beaumont for senior citizens, now known as the Chorleywood Beaumont Nursing Home.

Original Text by Brenda Bell with added contributions by Les Mead 22-04-2021